What I don’t really like about the Micro Swiss direct drive extruder is the long filament path to the nozzle. Most of the people buy this direct drive extruder for Ender 3, Ender 5 and CR-10. This extruder setup seems nice because it’s an easy drop-in replacement for Creality machines, and it has dual gears for better filament grip.

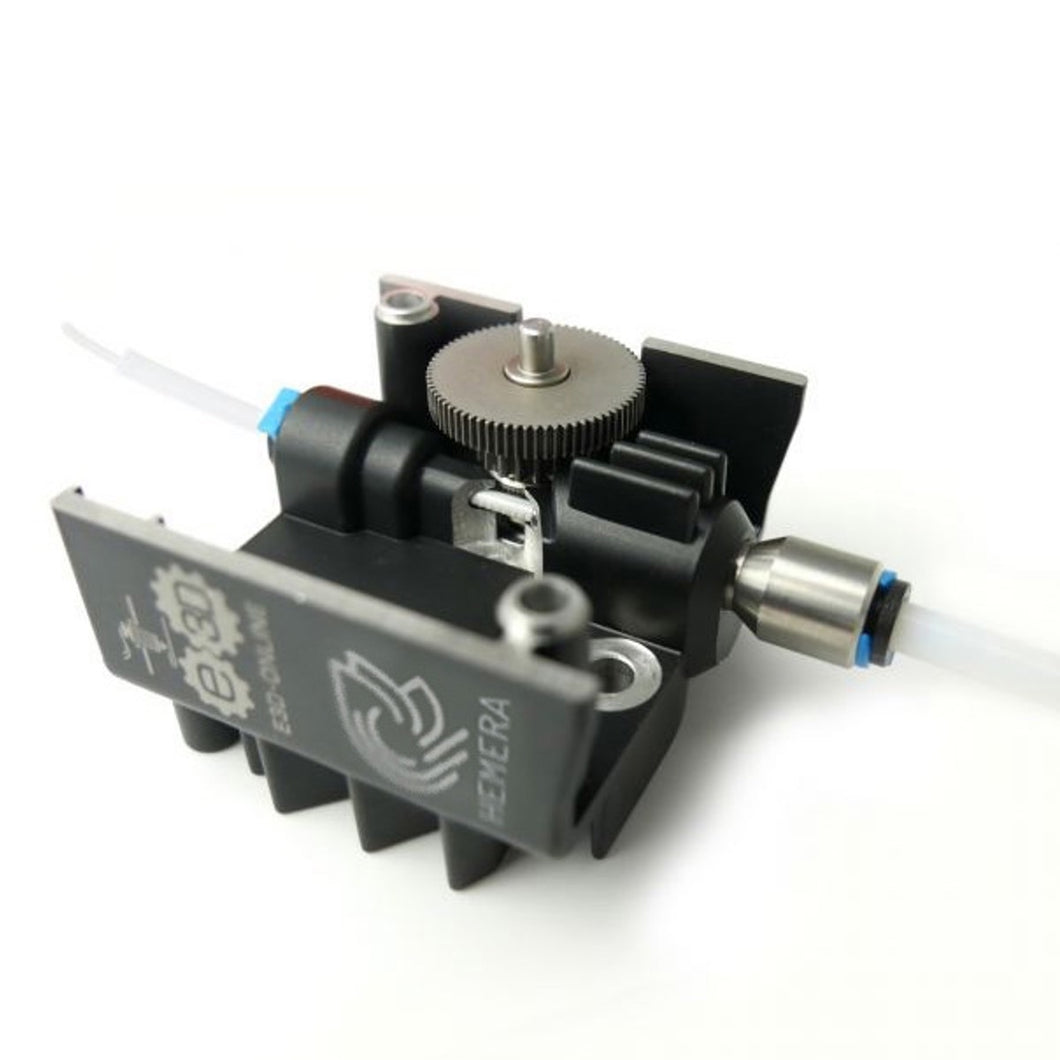

HEMERA E3D UPGRADE

If you also want to upgrade the hotend, then it’s going to cost around 100$.

With this extruder, you can convert your Creality printer to direct drive with a ~60$ investment. The Micro Swiss direct drive extruder is also a popular solution for Creality users. The Orbiter Extruder can be purchased from the following websites:Īmazon Printable Direct Drive Extruders Voron Afterburner

It’s more compact than the regular BMG + V6 setup but can’t really say if it’s better or not. I would recommend getting the Orbiter extruder if you like tinkering with your printer and want to use a direct drive extruder which is open source. Just need to decide which is the lucky printer which will get it. Besides that, the filament path will also be a bit longer compared to the BIQU H2 or Hemera/Matrix extruders.Įither way, the orbiter extruder looks interesting, and I’m considering ordering one because for around 50$, it could be a good open-source alternative. This is because of the type of stepper motor used in its construction.Įven though the Orbiter extruder is probably the lightest extruder currently available, keep in mind that when you add the mount, fans and the hotend, weight might come close to other extruders available on the market. It’s an open-source extruder made by Robert Lorincz and it weighs only 140g which is quite impressive. If you haven’t heard about the Orbiter extruder, I don’t really blame you. The Trianglelab Matrix Extruder can be purchased from the following websites: You will be able to improve print quality without compromising on the maximum speed you can achieve with your printer. For example, I would choose this for an Artillery Sidewinder X1, Genius, or a Creality CR-10. I recommend getting the Trianglelabs Matrix for large format 3D printers who already have a quite heavy heatbed. Even so, don’t let the weight deter you from grabbing one if you like it. It’s one of the best direct drive extruders available right now, but it’s also one of the heaviest. I previously reviewed the Trianglelabs Matrix and it performed really well. This makes the thermal performance a bit better while also requiring less airflow. The main difference between the Matrix and the Hemera is the use of a bi-metal heat break instead of the regular titanium heat break used on the Hemera. This will make the Trianglelab Matrix an easy upgrade because of the huge selection of mounts and fan ducts available. It’s cooled by a 4010 fan and it maintains compatibility with all the designs made for the Hemera. The heatsink has a different design, but otherwise it looks remarkably similar. The Trianglelabs Matrix has a big resemblance of the E3D Hemera.

With a bowden setup, you will be severely limited by the speed you can print these materials, and on some printers it’s not even possible.Ī lot of people upgrade to a direct drive extruder specifically for printing flexibles faster and with better quality. Even so, regular speeds of about 60mm/s should be easily achieved without much ringing.Īnother benefit of running a direct drive extruder is the possibility of printing flexible filaments, like TPU, TPE, Ninjaflex and others. Because the motor is next to the hotend and it moves during printing, you won’t be able to push speeds as high as with a bowden setup. There’s also a drawback for direct drive extruders and that’s weight. Retraction will be much lower compared to a bowden setup, and you can even set it to 0 with some direct drive extruders and proper calibration of linear advance/pressure advance. Because the filament path from the extruder to the nozzle is much shorter compared to a bowden setup, you will be able to tune your extrusion much easier. The main reason to buy a direct drive extruder is to have better control of your filament. 5 Wrapping Up Why buy a Direct Drive Extruder?

0 kommentar(er)

0 kommentar(er)